當前位置:首 頁 > 產(chǎn)品中心 > 紙箱成型機

全自動紙箱成型機E7

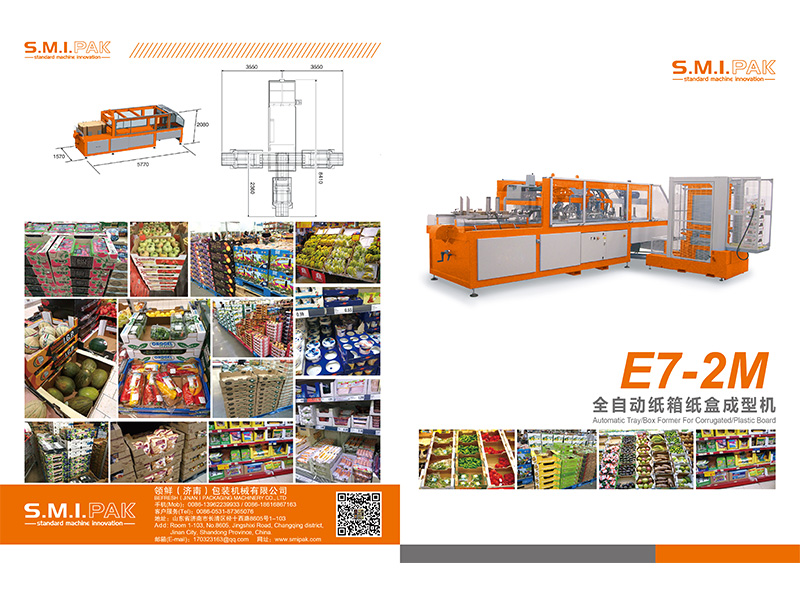

AUTOMATIC FORMER MODEL E-7 FOR THE FOLDING AND GLUING OF CORRUGATED BOARD TRAYS WITH REINFORCED CORNER POSTS-WITH OR WITHOUT TOP FLAPS

SMI PAK E-7全自動立柱或無立柱紙箱成型機+ES堆垛機

Picture of a E-7 with ES stacker (option & reference) 設備圖片僅供參考,以實物為準

CYCLE DESCRIPTION

工作描述

A single blank is picked by means of suction caps from a magazine where the cardboard sheets lie horizontally. 真空吸盤在水平料倉吸取紙板;After the blank is place onto the main transport chain, datum lugs fitted on the chain transport the blank to the forming stations. At this point glue is applied and the corner flap is mechanically pre-folded at a 90 degree angle.

紙板通過鏈條帶動推桿向前移動,立柱的搖蓋在設定位置,通過機械動作完成90度的預折;

By means of a special dedicated system developed by SMI PAK, the blank stops in the final folding and pressing station where the forming of the corner posts is completed accordingly to standard shapes and sizes that can be erected on the machine.通過SMI PAK獨立開發(fā)的機構(gòu),紙板停止在折疊成型位置,完成立柱的成型。紙箱要符合機器成型的標準箱型和尺寸。

From here, the partially formed blank is transferred to the forming area after further glue lines have been applied.

完成立柱成型后,紙板移動到成型區(qū)域,并完成相應位置的施膠;

Next, the blank is placed precisely into position under the press/mandrel, which completes the construction of the tray inside the forming station.

接下來紙板被精準的推送到成型模具下方,并在成型區(qū)域內(nèi)完成紙箱的成型;

The individual trays then fall through the forming station onto a conveyor belt below which transports them to the SMI PAK ES stacker(optional).

成型后的紙箱跌落在下方的輸送帶上,傳送到SMI PAK ES堆垛機(可選)。

MAIN FEATURES OF THE MACHINE

主要功能

Robust frame in welded and painted steel.

加強的碳鋼機架,防銹噴涂處理;

High capacity horizontal blank magazine.

高速水平料倉;

Easy adjustments of blanks supports in the magazine by means of platform escales. 料倉紙板尺寸調(diào)節(jié)便捷;

The blank is picked from the magazine by suction cups, driven by Venturi meter generated vacuum( one Venturi system for each vacuum cup).

吸盤在料倉里吸取紙板,文丘里系統(tǒng)產(chǎn)生真空,每一只吸盤由一只閥組系統(tǒng)控制;

The adjustment of suction cups positioning accordingly to blank dimensions is highly accessible and can be accomplished from the outside of the machine.

Top moving blank guiding system allowing to run bending cardboard sheet.

吸盤位置根據(jù)紙板的尺寸調(diào)整,可以在機器外部完成,導桿機構(gòu)可以保證彎翹紙板的進料。

Extra blank transport system combing motor-driven and skate wheels together, which allows to run thin and light cardboard sheets.額外的紙板進料系統(tǒng),可以整合電機驅(qū)動和滑輪機構(gòu),實現(xiàn)薄的輕的紙板進料;

Mechanical corner pre-folding system by means of flap lifting devices.

機械提升裝置,完成立柱的預折疊;

Transport system of the cardboard sheets by means of a specifically designed motor driven transport chain with datum lugs and frequency inverter, which allow to vary production speed at any time. The main feature of this transport chain is the possibility to stop the blank to allow an accurate forming of the corners despite the continuous constant speed.

進料機構(gòu)由單獨的電機驅(qū)動鏈條,帶編碼器和變頻器,可以調(diào)節(jié)進料速度。該功能可以滿足恒定速度連續(xù)生產(chǎn)下,紙板能準確地停留在立柱成型位置。

The position of the chain can be adjusted so that the position of corner pressing devices will not change.

鏈條的位置可調(diào),所以立柱成型結(jié)構(gòu)的位置不需要變化;

Corner folding units, one on each side of the machine, composed of one pneumatic folding device for open corners, or two folding devices for closed corners(option).

立柱成型單元,兩邊各一只氣動成型裝置用于開口立柱箱的成型,或者兩邊各兩只氣動成型裝置用于封閉立柱箱的成型;(可選)

Corner pressing units, one on each side of the machine. Adjustments can be carried out through hand wheels with platform e indicators. The change over from open to “L” shaped corner type is very easy and intuitive. Changeover parts not required.

立柱成型可以通過手輪調(diào)節(jié)完成開口立柱或L型的更換,直觀方便,不需要更換配件;

Lifting system of the pressing units grants an easy removal of cardboard sheets in case of need, or in the event of a maintenance service or cleaning of the machine. In compliance with the related safety rules, the system is equipped with a mechanical lock which protects the machine operator from harm.

專利設計的提上系統(tǒng),當需要的時候或者維護清潔機器時,用于紙板的剔出。根據(jù)相關的安全規(guī)則,設置安全機械鎖,保護操作人員不受傷害;

Press unit for the forming of the trays, operated by the vertical movement of the mandrel. The mandrel size depends on the size of the tray to be erected.

垂直移動的成型模具完成成型動作,尺寸根據(jù)成型的紙箱尺寸調(diào)整;

Tray forming station equipped with hoppers and pneumatic devices for the folding of top and side flaps. This station also features tray stopping units, as well as devices granting a correct ejection of the tray.

成型位置由成型區(qū)和氣動裝置,完成上部和邊上的搖蓋折疊。設置停機和紙箱剔出裝置;

The machine also features: 機器其它功能:

Fast changeover system thanks to hand wheels with platform e indicators. Quick replacing of the mandrel, when necessary for the change over.

通過手輪和計數(shù)器快速的調(diào)節(jié)和更換模具;

Two fold adjustment of side blank guides: this system is both present under the magazine and in the forming area, thus allowing independent adjustments of the guides at the front and at the back of the machine. This helps compensate any possible width variation of the blanks after the forming of corners.

兩邊的紙板導軌在料倉和成型區(qū),可以獨立調(diào)節(jié),以適應立柱成型前后寬度的變化;

Adjustments are carried out by means of screws and platform e counters.

通過螺桿和計數(shù)器來調(diào)整;

Hot-melt gluing system. The basic configuration is composed of a tank/pump unit, 4 pipes and 4 spraying heads.

熱熔膠系統(tǒng),基本配置膠缸,膠泵和4管4槍;

Reinforced supports for the spraying heads, so as to assure the precision of the glue lines.

噴槍壓力補償,以保證膠線的精準施膠;

Transparent mechacrylate safety interlock guards with aluminum frame. In particular, the micro switches on the side guards are mechanically locked until the corner pressing unit is completely lifted.

鋁型材框架,護欄安全接近開關關閉,直到成型模具完全升起;

Switchboard 操作面板

HMI with user friendly interface with touch screen panel for an easy access to all machine data(i.e. processed format, machine status and fault listing). Storage capacity: 100 programs.

人機界面,觸摸屏操作。可顯示工作狀態(tài)、參數(shù)和報警信息等,可存儲100個 模塊;

The machine is supplied with the touch screen panel positioned as standard, yet it can be placed on the opposite side on request.

機器的觸摸屏可以裝在標準位置,也可以根據(jù)要求安裝在另外一邊;

Painting: frame RAL 2004; panels RAL 7035;

油漆: 框架RAL2004, 面板RAL7035;

Machine designed and manufactured according to the related CE safety rules 2006/42/CE(2004/108/CE et 2006/95/CE)

歐盟標準認證。

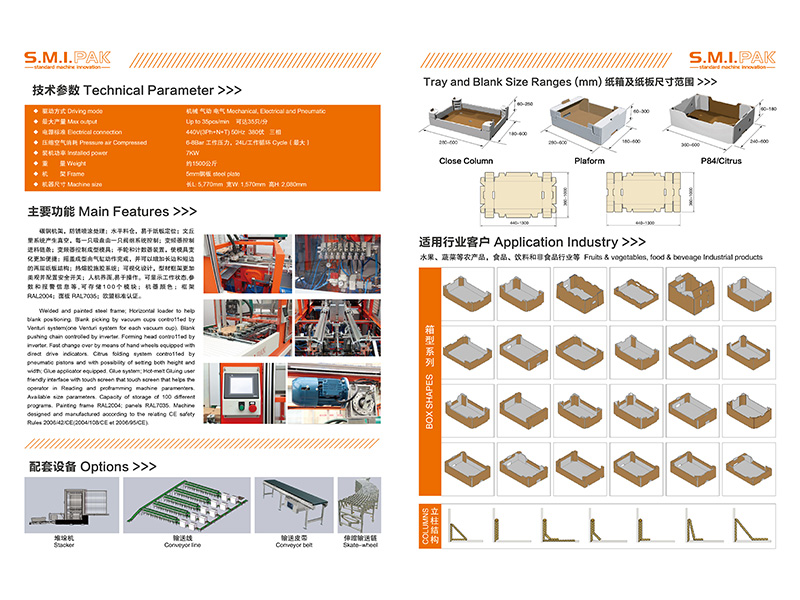

TECHNICAL DATA

技術參數(shù)

Speed: 35 trays/minute (Trays with reinforced corner posts).產(chǎn)量:35只/分;(立柱形開口箱)

Production speed depends on board dimensions and quality.

實際生產(chǎn)速度與紙板尺寸和質(zhì)量有關;

Electrical supply: 400V-50HZ 3 phases + N + G

電源標準:400 V – 50 Hz 3 phases + N + G (國內(nèi)380V)

Control voltage: 24V DC

控制電壓:24 VDC

Working temperature: from 5°C-35°C

工作溫度:5°C-35°C

Installed power: 7 KW

裝機功率:7 KW

Air consumption: 24.2NL/Cycle at 6 Bars.

壓縮空氣:24.2升/循環(huán),工作壓力6公斤;

Weight: 2400 KG approx with molds and parts

重 量:約2400公斤(帶模具及配件)

DIMENSIONAL LIMITS 尺寸范圍

Blank dimensions (LxW): min. 430x330 mm

紙板尺寸 max. 1.300x1.000 mm

Citrus trays dimensions (LxWxH): min. 280x180x60 mm

紙箱尺寸 max. 600x600x250 mm

Height without corner: 300mm

備注: 沒有立柱結(jié)構(gòu),高度可達300毫米。

sizes included in the supply, as specification from the customer

具體樣品尺寸,由客戶提供。